Copyright: © 2023 by the authors. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution 4.0 International License. J. Hortic. Sci. Technol. © 2023 Pakistan Society for Horticultural Science.

ABSTRACT

Seed propagation technologies are becoming increasingly popular among vegetable producers in developing countries due to their ability to provide benefits by lowering production costs. We assessed the costs and benefits of seed propagation technology adoption for tomato and sweet pepper production using a partial budget approach for seedling trays or field nursery technologies in the districts of Arumeru and Mvomero in Tanzania. We applied Net Present Value, Cost–Benefit Ratio (CBR) and Internal Rate of Return (IRR) to choose the best seed propagation technology that can be adopted by farmers and especially those producing vegetable seedlings as their core business and for commercial purposes. We collected the data using a household survey questionnaire, interviews, and focus group discussions. The results show that switching from field nurseries to seedling trays is economically beneficial by increasing the rate of return value to 3.02, which is greater than one, implying a rate of return of 302 %, which is greater than the costs of new investments. Overall, we can conclude that farmers were less likely to grow vegetable seedlings in seedling trays due to the fact that seedling tray technology was considerably more expensive than field nursery technology. As a result, we recommend that policymakers at all levels of local and central governments promote extension agent training in this technology to promote seedling tray propagation among vegetable farmers and make the technology affordable to farmers in order to increase agricultural productivity, income, and well-being.

INTRODUCTION

Vegetables are important dietary components and sources of income, particularly in urban and peri-urban areas. These crops are a low-cost source of proteins, vitamins, and other essential nutrients for human health and well-being (Temesgen and Reta, 2015; Chatzopoulou et al., 2020; de Sousa and Solberg, 2020). Also, vegetables are effective in preventing micronutrient deficiencies and diseases (Rodriguez-Casado, 2016; Skoczek-Rubinska et al., 2018). As a result, they are in high demand among those who cannot cultivate them, creating opportunities for smallholder farmers as a source of income and livelihood (Xaba et al., 2013; Qumbisa et al., 2020; Sinyolo et al., 2020). Moreover, vegetables generate employment opportunities in industries such as marketing, processing, and transportation (Ajewole and Folayan, 2008; Kalne et al., 2018).

In the coming decades, the global demand for horticultural products is projected to increase significantly due to a greater understanding of their nutritional value and the subsequent rise in their consumption. This demand presents an opportunity to absorb Tanzania’s ever-increasing unemployed labour force (ESRF, 2010). As a result, efforts to boost the vegetable subsector could have a positive effect on people’s living standards and contribute to the food security of households and communities in general.

Tanzania has favourable climatic conditions for growing a variety of vegetables, with the Northern Highlands zone (Arusha, Manyara, Kilimanjaro, and Tanga regions) having the greatest potential for diverse horticultural investments, followed by the Eastern zone (Dar-es-Salaam, Morogoro, and Coast regions), the Southern Highlands zone (Iringa, Njombe, Ruvuma, Katavi, and Mbeya regions), and the Central and Lake Zone (ESRF, 2010; Putter, 2007; MAFS, 2002). Vegetables are estimated to account for more than half of the country’s non-staple food production, with a per capita consumption of approximately 60 kilogrammes (NBS, 2019). According to NBS (2017), vegetables comprised approximately 0.67 % of total crop production area at the national level.

Global vegetable production in 2019 was roughly 1.13 billion metric tonnes (FAOSTAT, 2019). China was the world’s largest producer of fresh vegetables, with an approximate production value of $25.25 billion USD. India, Vietnam, Nigeria, and the Philippines are also substantial vegetable producers (FAOSTAT, 2019). According to the Asian Vegetable Development Research Centre, this is marginally greater than the projected production level for 2,000 of 10.3 million metric tonnes (AVRDC, 1990). However, despite of the favourable conditions for vegetable production in Tanzania, the country has yet to reach its full potential. In addition, despite its comparative advantage in climatic conditions, reliable and well-distributed rainfall, and adequate labour, Tanzania is not performing well in terms of productivity in comparison to other East African nations (ESRF, 2010). According to FAO statistics, Kenya ranked 90th in the world for vegetable production in 2013, producing approximately 142,872 t/ha, while Tanzania ranked 154th, producing approximately 72,476 t/ha (FAOSTAT, 2014).

About 70 % of Tanzania’s vegetable growers are small-scale farmers with less than 2 hectares (TAHA, 2010). The dominance of small-scale farmers in vegetable production presents an opportunity for poverty reduction through income and employment generation (James et al., 2010; ESRF, 2010), despite of the fact that farmers are characterised by low levels of productivity due to, among other factors, lack of technology in seed propagation and the use of traditional seeds that produce poor seedlings (AVRDC, 2014; Liu, 2013; Temu and Temu, 2006). Low-quality seeds and planting materials hinder agricultural output (MAFS, 2002). This reduces the ability of smallholder farmers to satisfy rising demand in developed nations and urban areas (UN, 2003). Utilizing seedling trays and other innovative techniques to cultivate vegetable seedlings in nurseries could increase vegetable production (Odhiambo, 2021). This is due to the situation that self-pollinating plants such as vegetables are typically propagated from seeds (Tewari, 2009; Faust et al., 2016). Therefore, according to Ratha et al. (2014), some farmers do utilise scarification, alternating temperatures, and chemical treatments to promote seed germination.

The handling and management of seedlings in a nursery affects their post-plant survival, growth, and yield (Munjuga et al., 2013). Consequently, seed quality and method determine seedling quality and yield (Putter et al., 2007). However, the majority of Tanzanian farmers plant untreated seeds at random in sunken beds (SEVIA, 2014), and as a result, the majority of seedlings suffer from diseases such as dumping-off, a fungus that degrades seedlings due to excessive moisture and air circulation (Bok et al., 2006; (Rais and Sheoran, 2015; Brasil and Siddiqui, 2018). In this situation, these farmers experience low transplant survival which reduce the yields of vegetable farmers (Brasil and Siddiqui, 2018).

Government of Tanzania (GoT), private, and international agencies such as the former Asian Vegetable Research Development Centre (AVRDC), which is now known as World Vegetable Centre (WVC), the Seeds of Expertise for the Vegetable Industry in Africa (SEVIA), and International Institute of Tropical Agriculture (IITA) have attempted to intervene in order to address the problem of poor quality seedlings by introducing the use of seedling trays in seedling production (TAPP, 2015; SEVIA, 2014). Compared to the use of nursery beds, growing seedlings in trays has many advantages. This is due to the fact that the use of seedling trays is an effective method for enhancing the quality of seedlings, as they are designed to provide a separate area for each seed to germinate and grow, with adequate air circulation and drainage (Bhimraj, 2011; Lin et al., 2017). According to Everaarts et al. (2011), the efficiency of transplanting in seedling trays could be improved by raising seedlings in trays, a viewpoint shared by SEVIA (2014), which estimates that seedling trays produce 25 % to 48 % more plants than nursery beds, with a seed use efficiency of 70 % compared to 40 % for nursery beds. In addition, the use of trays results in a loss of one to two seedlings, if any, compared to a loss of approximately 25 % in nursery beds. However, despite the stated benefits of trays, the majority of farmers continue to use nursery beds to raise seedlings, although the reasons for this are not fully established (TAPP, 2012; HODECT, 2010).

Several studies have demonstrated that investing in a particular seed propagation technology could increase farmers’ profits. In addition, a lack of comprehension of the costs and benefits of new technology by farmers may prevent them from adopting it and realising the anticipated profits (Michler et al., 2019). However, despite the fact that farmers may be interested in adopting improved vegetable seed propagation technologies, they lack adequate knowledge of the associated economic benefits (Ajayi and Solomon, 2017; Misaki et al., 2018). Consequently, an analysis of the costs and benefits of using one technology versus another demonstrates the anticipated benefits of the proposed technologies. This study employs a cost-benefit analysis methodology so that farmers can estimate the probable costs and benefits of available technologies. The methodology is also crucial because it allows decision-makers to evaluate the opportunity cost of adopting one technology over another. Therefore, it helps businesses determine what additional benefits they could have obtained if they had chosen a different option. Few studies have been conducted in the districts of Arumeru and Mvomero on the benefits that vegetable farmers anticipate from utilising vegetable nursery seed production technologies as opposed to field nursery seed propagation technologies. Therefore, the purpose of this study is to determine the costs and benefits of utilising vegetable nursery seed propagation technology in the districts of Arumeru and Mvomero, Tanzania.

This study is guided by the theory of welfare economics whereby some governments do compare costs and benefits associated with projects and choose not only the best alternative for the benefit of community but also for the efficient use of public resources (Nas, 2016). Therefore, one of the decision tools used in welfare is the Cost-Benefits Analysis (CBA), and it is the one that has been adopted in this study.

Badolo (2017) identified a number of factors that should be considered when implementing CBA in agricultural projects. These include the use of standard definitions and measurements, in addition to their estimations. These are the definitions used in evaluating agricultural projects: Average yield is the amount of product produced per unit of land. The yield is expressed as kg/ha; (ii) Output prices: Typically, farm gate prices are utilised to calculate returns. The farm gate price of the output is the value (price) farmers receive or are able to receive for their harvested crops. In other words, it is the final price received by farmers at the conclusion of the production process. (iii) Gross return: the gross return is equal to the product of the farm gate price and the adjusted yield; (iv) Total variable input costs: The total variable input cost is the sum of all variable input costs and differs between treatments. These are the farm gate costs for each treatment’s variable inputs. Included in the analysis’s inputs are seed, labour, fertilisers, pesticides, and packaging; (vi) Marginal rate of return: is the percentage change in net returns due to the introduction of the technology. It is expressed as a percentage and represents the ratio of increased benefits to increased costs.Therefore, the use of CBA was employed in this study, in order to determine the performance and profitability of different seed propagation technologies employed by farmers. This is because CBA is an economic technique that measures, weighs, and assesses the total costs of an investment against the benefits in monetary terms so as to choose the best or most profitable option (Boardman et al., 2006). Hence, for this case it is suitable for determining the most profitable nursery propagation technology. Costs and benefits analysis is carried out using financial costs and financial benefits of the venture and assists in making economic decisions of any kind using tools: like Net Present Value, Cost–Benefit ratio (CBR) and Internal Rate of Return (IRR) which were also applied in this study to choose the best nursery or seed propagation technology that can be adopted by farmers and especially those producing vegetable seedlings as their core business and for commercial purposes.

The study areas

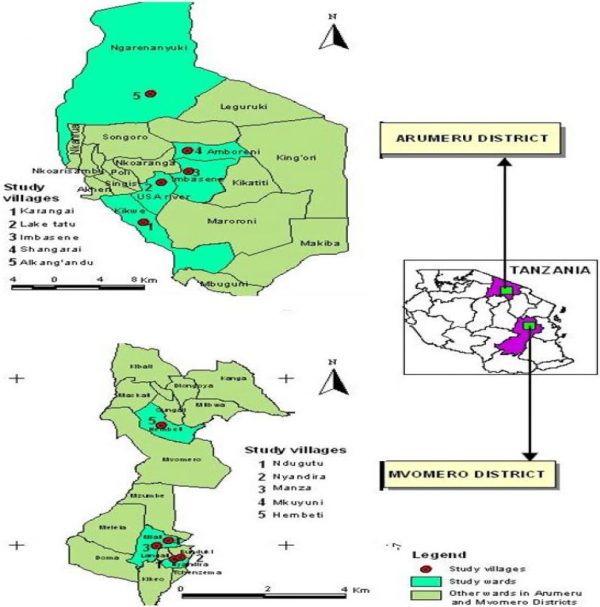

The study areas were the districts of Mvomero and Arumeru in Tanzania (Fig. 1). According to Private Agriculture Sector Support (PASS, 2013), the districts have a high horticultural potential and employ numerous seed propagation technologies. Mkuyuni, Manza, Nyandira, Ndugutu, and Hembeti were Mvomero’s study villages, while Lake Tatu, Karangai, Shagharai, Imbaseni, and Alkang’adu were Arumeru’s. According to (Kajembe et al. (2005), the Arumeru district is located 30 degrees south of the Equator and 360 degrees east of the Greenwich Meridian. Arumeru experiences two wet seasons from September to December, with heavy precipitation expected from March to June. The precipitation patterns of the highlands and the lowlands differ. The highlands receive between 800 and 1200 mm of precipitation, while the lowlands receive between 500 mm and 700 mm. Cold season’s average monthly temperature ranges between 20 °C and 17 °C. Chinese cabbage, sweet pepper, nightshade, and tomatoes are among the vegetables cultivated.

Figure 1: The study villages are depicted on a map of the Mvomero and Arumeru districts.

Northeast of Morogoro, between 370 and 280 degrees East of the Greenwich Meridian and 80 and 100 degrees South of the Equator, is the Mvomero district (Sefa and Beed, 2012). The first rainy season occurs between October and December. March through May is the wet season. The precipitation patterns of the highlands and the lowlands differ. Highlands receive approximately 2000 mm of precipitation, while plains receive over 600 mm. The lowlands of Mvomero are 30 °C, while its peaks are 18 °C. The vegetables grown in Mvomero and Arumeru are comparable.

Procedures for sampling and data collection

The selection of regions, districts, and wards utilised a multistage sampling method. At first, Arusha and Morogoro were selected because of their prominence in vegetable cultivation. Second, the districts of Arumeru and Mvomero were selected due to their significance in vegetable production using various seed propagation techniques. The third stage involved selecting study villages from each district according to the following criteria: vegetable production, seed propagation technologies, vegetable type produced, and proximity to SEVIA, TAPP, AVRDC/WVC, and TAHA priority research areas where the sustainable intensification of farming system project was implemented (PASS, 2013). A simple random procedure was used to select 240 farmers from vegetable-growing regions as study participants.

A household survey questionnaire, interviews, and focus groups were utilised to collect primary data. The demographic characteristics of farmers (e.g., age, gender, level of education attained), institutional factors (credit access and extension services), and farm characteristics (e.g., inputs used and their prices, costs incurred in raising vegetable seedlings, types of seed sown, and actual crop area), and constraints encountered are among the data collected using these techniques. District Agricultural Officers, journals, and grey literature, as well as numerous seed propagation technology documents were consulted in order to collect secondary data. These data include profiles of districts, including their location, rainfall, and temperature patterns, as well as villages with a high concentration of vegetable production.

Data analysis

A partial budget estimated tray costs and benefits for vegetable seed propagation. A partial budget study focuses on changes in income and expenses to show how a decision will affect farm profitability. Because alternative seedling technology only partially uses expected vegetable production change, a partial budget approach was used.

This study did not include the partial budget’s change-related income reduction (Hassan, 2016). Costs for seedling trays, planting materials, other inputs, depreciation, and agricultural labour including sowing, watering, seedbed preparation, fertiliser application, media preparation, and tray filling were also estimated. Input costs were calculated by multiplying unit price by number of items purchased. Estimating the average labour cost per man-day for each activity was used to calculate the opportunity cost of using one’s own resources. Straight-line depreciation was used (Kuter et al., 2018), and the salvage value was set to zero, indicating that the trays could not be reused after their service life. The seedling trays were assumed to last for three years, depending on care. Using survey data and previous research (Khaliq et al., 2020; Bhimraj, 2011), the service life of seedling trays was calculated.

Additionally, the lower price includes fertiliser and pesticide costs, as the use of trays requires less of both. The sale price of seedlings was used to estimate an increase in income. Sastry and Zitter (2014), Lin et al. (2017), Waiba and Sharma (2020), and Singh (2021) argued that seedlings raised in trays are more vigorous, healthy, and disease-free than those raised in nursery beds, thereby increasing their market value.

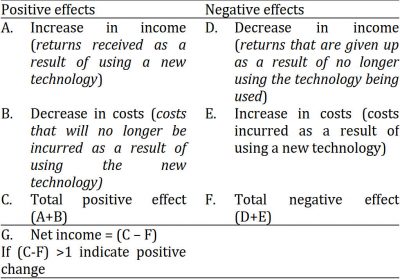

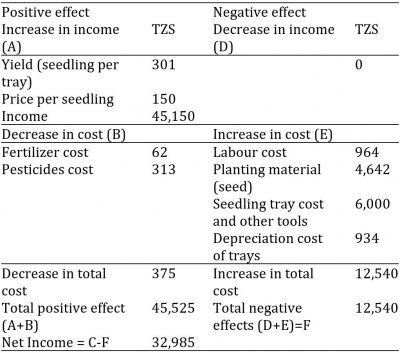

Budget format is in Table 1. Right side of partial budget lists losses (positive effects) and left (negative). The partial budget’s return rate helped evaluate new technology’s economics. It calculates each expense’s impact on net income. To calculate return on new technology, equation 1 was used.

Table 1: Partial budget format.

Decision: If the net benefit is positive, then the alternative may have some economic advantages while if the net benefit is negative the business/producer would be better off staying with the current situation or look for a different alternative.

Rate of return = ∆ Net income ∕ ∆ Variable costs……………………(1)

Whereby

∆ Net Income = ∆TR- ∆VC……………………………………………………..(2)

At a significance level of 5 %, an independent T-test sample was used to find out if there was a statistically significant difference between unit production costs and the value of the technology. In equations 3 and 4, it was assumed that using seedling trays to grow seedlings would cost more than using nursery beds, which was what was expected before.

H0 : Xst = Xnb ………………………………………………………………….……(3)

Hα: Xst > Xnb ……………………………………………………………………….(4)

Where Xst means of seedling trays, and Xnb means of nursery beds.

A key assumption was made when analysing the partial budget’s costs and benefits. The study assumes farmers are rational in their pursuit of maximum profit and sell seedlings at a reasonable market price to cover costs. Farmers intended to grow seedlings for transplanting into the main plots. They were expected to adopt a technology that allowed them to produce more seedlings for their main plots and surplus for sale. Post-nursery activities were assumed to be the same regardless of technology, which was not always true.

Characterization of seed propagation technology

According to the findings, some vegetable seeds, such as carrots and amaranth, were planted directly in the main field, while others were planted in nurseries. Nursery beds and seedling trays were the most prevalent technologies for sowing vegetable seeds in nurseries. In other words, some vegetable growing farmers utilised nursery beds while others utilised seedling trays. Moreover, because traditional nursery techniques were less expensive, less complicated, and more familiar to them, some vegetable producers opted to use them. Few foresighted farmers who had access to credit, extension services, and production in close proximity to vegetable production experiment sites utilised seedling trays. When asked where they learned seedling techniques, many farmers responded that their parents taught them. Consequently, one of the farmers stated,

According to an interview response from a 45-years adult male farmer from Karangai Village in Arumeru district in July 2017, “It’s a good technology because it requires less labour and water than we do.”

During a discussion with farmers in Hembeti and Lake Tatu in Mvomero and Arumeru districts over the use of tray nursery bed June 2017, it was reported that “seedling tray technology was good, but it was only designed for progressive farmers and those who could afford to acquire the technology because they had access to financial resources“.

Moreover, despite the fact that farmers could have formed groups to improve their access to technology, they chose not to. Instead, each farmer chose to pursue his own interests. Regardless of the availability of new technologies, vegetable growing farmers adopted them slowly, demonstrating their resistance to change. This could also be attributed to the inability of change agents to persuade farmers to adopt the new technologies, resulting in resistance to change. Low adoption rates among farmers are most likely attributable to their attitudes toward seedling tray technology and the nature of their water infrastructure. This is because the majority of farmers in the study areas utilised nearly fallow irrigation to water their seedbeds and nurseries. Studies done in Asia (Afzal et al., 2019) and elsewhere across the globe show that for vegetable crops direct field seeding technology is a common propagation method for many vegetable crops including corn, peas, beans, and spinach.

Consequently, when compared to field nurseries, the use of seedling trays was relatively low, despite the benefits associated with their use to raise seeds being readily available and advantageous. Some of these benefits include enhanced germination, disease-free seedlings, and more efficient seed utilization. Moreover, vegetable farmers asserted that the seedling tray technology uses fewer seeds than planting seeds directly into the nursery bed, resulting in increased profits. According to Pandiyaraj (2017), the primary objectives of introducing seedling tray technology in India were to increase the efficient production of disease-free, high-quality seedlings and to cultivate early-maturing crops in open field conditions in order to maximise profits. Farmers in the study area reported that many seeds planted in field nurseries are lost due to pests and diseases because the majority of fields harbour a variety of vectors that predispose seeds to disease, as opposed to using seedling trays technology to raise seeds. In this study, we also argue that the continued use of field nursery technology by farmers is due to the high cost of trays, their lack of technical knowledge, and an inadequate understanding of the economic benefits of seedling tray technology.

Types of vegetables grown and amount of land used

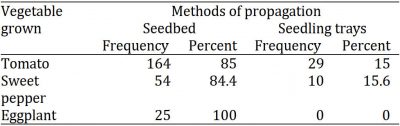

The findings show that tomatoes, sweet peppers, and eggplant are grown in the area of study. Tomatoes and sweet peppers were sown in both trays and nursery beds, whereas eggplant was planted directly in the field. In terms of seed propagation technology, tomato and sweet pepper seedlings were primarily grown in seedling trays, as shown in Table 2. Tomatoes and sweet peppers were the leading crops in terms of acreage, and consequently, their production and economic value were perceived to be greater. Due to the limited budget, only tomatoes and sweet peppers were selected for analysis, as they were the only vegetable crops in the study areas that utilised seedling tray technology, as none of the growers raised eggplant seedlings in seedling trays.

Table 2: Vegetables grown and seed propagation technology used.

In addition, farmers were found to be seasonally diversifying their vegetable production to include two or more vegetables in order to minimize the risk of price fluctuations, which were prevalent in tomato production. Farmers also reported that eggplant was typically planted to diversify their income sources due to its relatively lengthy harvesting season compared to other vegetables before it was completely uprooted from the field. In addition, farmers assert that eggplant production requires fewer field management practises, such as fertiliser application and pest control, in addition to weeding and watering. As a result, it is a vegetable crop used to mitigate risk and generate a steady income.

In addition, the majority of vegetable farmers grew tomatoes and eggplant on plots of less than one acre. Additionally, the majority of vegetable farmers grew tomatoes and eggplant on less than 0.5 hectares of land. According to Weerakkody and Mawalagedera (2020), similar trends are observed in the vegetable production industry of Sri Lanka, where vegetables are grown in small holdings (0.2-0.4 ha) on hilly terrains through continuous cultivation. We argue that the size of the plot in which vegetables are grown is crucial because it determines both the quantity of seed to be sown and the size of the nursery in relation to the spacing factor in the main plot. The average nursery size for both vegetables was 25 m2 per acre, and 33 trays were sufficient for those who used seedling tray propagation technology with a 60 cm by 60 cm spacing factor. In comparison to other vegetables, the average area under tomato cultivation was greater than half an acre, according to the findings. These findings are consistent with those of Putter (2007), who found that the average vegetable-growing area in Tanzania was 0.11 hectares. Vegetables growing farmers also claimed that land availability, water supply, production costs, and labour availability influence plot size in vegetable production. These findings are consistent with those of Ali and Abedullah (2002), who argued that vegetable farmers have fewer resources than non-vegetable farmers due to their smaller average farm size. However, the factors cited as impediments to vegetable cultivation are either location- or region-specific. For instance, land availability has been reported in the highlands of the Mvomero and Arumeru districts, whereas inadequate water supply has been reported in the lowlands, where vegetable production is relatively greater, such as in Lake Tatu and Hembeti villages.

Despite the difficulty of vegetable production by smallholder farmers, the nutritional and economic benefits to consumers and producers, respectively, make them an integral part of vegetable supply chains. Consequently, despite their small land size, vegetable farmers have a greater understanding of markets because they earn higher off-farm incomes and invest appropriately in land preparation for vegetable production (Ali and Abedullah, 2002).

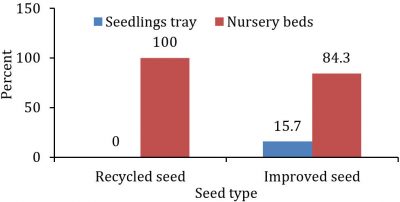

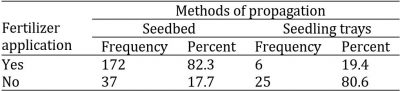

Types of seed sown propagation technology and fertilizer applications

As depicted in Fig. 2, the majority of vegetable growers utilised recycled seeds from the previous season’s harvest, whereas a minority used improved seeds. The nursery bed technology outperformed the seedling tray technology despite the use of hybrid seeds. Regardless of the seeds used, the manner in which vegetable farmers in the study areas grew their seeds was likely a factor in the amount of fertiliser they applied. According to Table 3, the majority of vegetable growers who cultivate seedlings in field nurseries apply more fertiliser than those who cultivate seedlings in seedling trays.

Figure 2: Type of seed used based on the technologies.

Table 3: Fertilizer applied based on methods of propagation.

These findings are consistent with those of Yosef et al. (2013) , who reported that farmers in Ethiopia’s central highlands used less fertiliser for seedling production during the establishment and management of community nurseries. Observations made during fertiliser application in vegetable plots revealed that industrial chemical fertilisers such as calcium ammonium nitrate, urea, and diammonium phosphate were most frequently used to feed the nursery bed seedlings.

In some instances, farmers did use organic manures such as farmyard manure (FYM) and compost. Despite claims that these manures were not readily available, farmers preferred to use industrial chemical fertilisers instead, despite their high cost. In addition, farmers assert that because chemical fertilisers are costly, only a minority of them apply them in the correct quantities, thereby reducing crop yields and productivity.

For instance, in the village of Shangarai, which was close to livestock keepers and had easy access to FYM, its use on the nursery bed was quite low. Farmers argue that improper preparation causes diseases, such as rust, in young plants. However, it has been suggested that when vegetable growers cultivate seedlings in seedling trays, they use fewer pesticides. This indicates that utilising a tray decreases the likelihood of seedling diseases, specifically damping off.

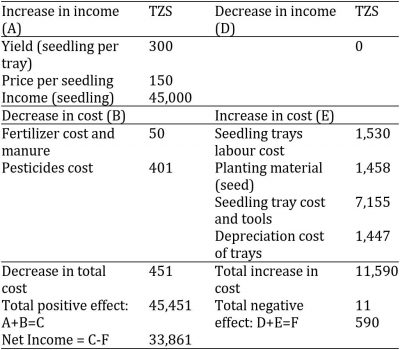

Costs and benefits analysis for seasonal tomato and sweet pepper seeds propagation technologies

Farmers’ use of seed propagation technologies was evaluated in terms of its costs and benefits using a partial budget analysis. In tomato and sweet paper seedling production, the choice was between using nursery beds or seedling trays (Table 4 and 5). The information provided in the positive effect side analyses reveals the increased income and decreased expenses that result from switching seed preparation technologies. In contrast, the additional cost results for this alternative analysis indicate a positive net income, which suggests that a farmer using seedling tray technology can earn 32,900 Tanzania Shillings (TZS) or About 14.3 USD (according to 2017 Exchange rate which was 1 USD equals to TZS 2,237) per tray. In contrast, the rate of return value of 3.02, which is greater than 1, indicates that the rate of return is 302 % greater than the cost of additional investments. This demonstrates that the proposed change in technology from field nurseries to seedling trays has an economic advantage.

Table 4: Partial budget for tomato choice for seedling trays over nursery beds.

Table 5: Partial budget for sweet pepper production choice using seedling trays over nursery beds.

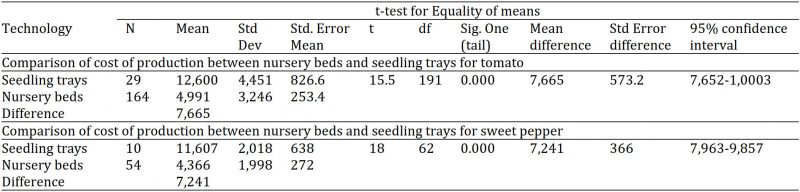

According to Table 6 of the cost-benefit analyses of technologies used on specific vegetable crops, the total mean nursery costs for the use of seedling trays and nursery beds were TZS 12,600 (USD 5.6) per tray and TZS 4,900 (USD 2.2) per square metre, respectively. As shown in Table 6, the average cost difference between nursery beds and seedling trays was statistically significant at p<0.01 according to the results of the significance test for differences in nursery costs. This indicates that the unit production cost for tomatoes grown in seedling trays was TZS 7,665 (USD 3.4) higher than for tomatoes grown in nursery beds, while the unit production cost for sweet peppers was TZS 7,241 ( USD 3.2) higher.

Table 6: Comparison of cost of production between nursery beds and seedling trays for tomatoes and sweet peppers.

Using seedling trays rather than nursery beds to raise sweet pepper seedlings would result in a net gain of TZS 33,800 (USD 15) per tray, according to partial budget results (Table 5). The rate of return is 3.64, which indicates that for each additional unit of expenditure, net income will increase by 364 %. Because of this, using seedling trays is less expensive than using nursery beds.

In addition, the results indicate that the total average nursery cost for growers who utilise seedling trays was TZS 4,300 (USD 2) and TZS 11,600 (USD 5.2) respectively, for cultivating plants in nursery beds and trays. The use of trays has a higher cost, which can be attributed to the purchase of trays as well as the increased labour required to fill the trays and prepare the media. As shown in Table 6, the average cost difference between nursery beds and seedling trays was statistically significant at p<0.01 according to the results of the significance test for differences in nursery costs. This indicates that seedling tray unit production costs were TZS 7,200 (USD 3.2) higher than nursery bed unit production costs. However, despite the fact that the costs of seedling tray technology were higher than those of nursery beds, their economic benefits were also greater.

CONCLUSION

This study evaluated the economic costs and benefits incurred by farmers in adopting and utilising one of two seed propagation technologies, seedling trays or nursery beds, over the other. The central question was whether a farmer would gain any additional benefits by switching from one technology to the other. Alternatively, will there be any additional expenses? Despite the benefits or economic advantages associated with the technology, the use of seedling trays in seed propagation technology for vegetable production was relatively low compared to field nurseries, according to the findings. In addition, the results indicate that vegetable farmers have small plots of land and a greater understanding of the markets they target for higher returns. Due to the nutritional value and higher profits associated with vegetable production, these markets also encourage farmers to invest more in vegetable production. Despite the availability of inputs, particularly vegetable seeds, farmers continued to use recycled seeds, according to the findings. In addition, based on the to-be-adopted nursery technology, the rate of return in tomato production was 302 % higher than the cost of additional investments, indicating that the proposed change in technology from field nursery to seedling trays technology has an economic advantage. The conclusion is that small-scale vegetable farmers will continue to favour nursery beds over seedling trays. Few of them use chemical fertilisers for seed propagation, but the majority of them use recycle seeds. It is also evident from a cost-benefit analysis that seedling trays are more useful and can yield higher returns than nursery beds.

RECOMMENDATIONS

According to the study’s findings, vegetable farmers should be encouraged to use seedling trays instead of nurseries. However, it is also recommended that the design and development of agricultural technologies be conducted in such a way that they are affordable to farmers and well known to extension agents who can provide vegetable growers with immediate technical support at the lowest possible cost. Also, timely availability of inputs such as fertilisers and other agrochemicals is suggested to encourage farmers to adopt new technologies. This will increase both the amount of vegetables that can be grown and the amount of money that can be made from vegetable cultivation.

Declaration of competing interests

The authors declare no conflict of interest.

Author contribution statement

All the authors were involved in the conceptualization of the study. Selina Nombo: Data collection, Equation development, Formal analysis and Writing original draft. Parit Saruni: Writing Reviewing and Editing. Jeremia Makindara: Supervision and editing of the draft manuscript up to the final submission. All authors read and approved the final manuscript for submission.

Funding

This study was funded by the Innovative Agriculture Research Initiative (IaGRI) under the Feed the Future USAID program.

Acknowledgments

The authors thank the Innovative Agriculture Research Initiative. We also appreciate the support from the Districts Agricultural and Livestock offices. Finally, we thank the anonymous reviewers and editors for their constructive comments, which substantially improved this study.

REFERENCES

Afzal, I., Shabir, R. and Rauf, S. 2019. Seed production technologies of some major field crops. In: Hasanuzzaman, M. (ed.). Agronomic Crops. Springer, Singapore, pp. 655-678. [Abstract/FREE full text, Google Scholar, CrossRef]

Ajayi, M.T. and Solomon, O. 2017. Influence of extension contact and farmers’ socio-economic characteristics on adoption of oil palm technologies in Aniocha north Local Government, Delta State, Nigeria. Journal of Agriculture, Science and Technology, 12(2): 35-46. [Abstract/FREE full text, Google Scholar]

Ajewole, O.C. and Folayan, J.A. 2008. Analysis of Technical Efficiency in Dry season Leaf Vegetable Production among smallholders in Ekiti State, Nigeria. Agricultural Journal, 3(4): 252-257.

Ali, M. and Abedullah, D. 2002. Nutritional and economic benefits of enhanced vegetable production and consumption. Journal of Crop Production, 6(1-2): 145-176. [Abstract/FREE full text, Google Scholar, CrossRef]

AVRDC. 1990. Vegetable Production Training Manual. Asian Vegetable Research and Development Center (AVRDC). Shanhua, Tainan, pp. 447. [Abstract/FREE full text]

AVRDC. 2014. Vegetable production training empowers farmers to achieve profitable growth in Babati, Districts, Tanzania. Retrieved from http://avrdc.org.

Badolo, F. 2017. Cost and benefit analysis of cropping systems for sorghum and maize production under the Africa RISING project in Mali. International Institute of Tropical Agriculture, Mali, pp. 7. [Abstract/FREE full text, Google Scholar]

Bhimraj, B. 2011. Resource book on Horticulture, Nursery Management. Yashwantrao Chavan Maharashtra Open University, Nashik, pp. 268. [Google Scholar]

Boardman, A.E., Greenberg, R.A., David, L.V. and Frontmatter, W. 2006. Cost-Benefits (3rd Ed.). Cambridge University Press., United Kingdom, pp. 27.

Bok, I., Madisa, M., Machacha, D., Moamogwe, M. and More, K. 2006. Manual for Vegetable Production. Department of Agricultural Research, Gaborone, Botswana, pp. 57.

Brasil, I. M. and Siddiqui, M.W. 2018. Postharvest quality of fruits and vegetables: An overview. In: Siddiqui, M.W. (ed.). Preharvest Modulation of Postharvest Fruit and Vegetable Quality. Academic Press. pp.1-40. [Abstract/FREE full text, Google Scholar, CrossRef]

Chatzopoulou, E., Carocho, M., Gioia, D.F. and Petropoulos, S.A. 2020. The beneficial health effects of vegetables and wild edible greens: The case of the Mediterranean diet and its sustainability. Applied Sciences, 10(24): 9144. [Abstract/FREE full text, Google Scholar, CrossRef]

de Sousa, K. and Solberg, S.Ø. 2020 Conservation gaps in traditional vegetables native to Europe and Fennoscandia. Agriculture, 10(8): 340. [Abstract/FREE full text, Google Scholar, CrossRef]

ESRF. 2010. Strengthening Micro Enterprises in Tanzania: The Case of Small-Scale Vegetable Farmers in Arusha. [Abstract/FREE full text, Google Scholar]

Everaarts, A.P., Putter H. and Amon, W. 2011. A survey of field vegetable production in Tanzania, recommendations for improvement. Retrieved from http://edepot.wur.nl/195026. [Abstract/FREE full text, Google Scholar]

FAOSTAT. 2014. Food and agriculture data: Crops production. In: Food and Agriculture Organization of the United Nations, Italy. [Abstract/FREE full text]

FAOSTAT. 2019. Food and agriculture data: Crops production. In: Food and Agriculture Organization of the United Nations, Italy. [Abstract/FREE full text]

Faust, J.E., Dole, J.M. and Lopez, R.G. 2016. The floriculture vegetative cutting industry. Horticultural Reviews, 44: 121-172. [Abstract/FREE full text, Google Scholar, CrossRef]

Hassan, A., Ijaz, S. S., Lal, R., Barker, D., Ansar, M., Ali, S. and Jiang, S. 2016. Tillage effect on partial budget analysis of cropping intensification under dryland farming in Punjab, Pakistan. Archives of Agronomy and Soil Science, 62(2): 151-162. [Abstract/FREE full text, Google Scholar, CrossRef]

HODECT. 2010. Tanzania Horticultural Development Strategy 2012-21. Horticultural Development Council of Tanzania, pp. 26. [Abstract/FREE full text]

James, B., Ahowe A.C., Godono, U.I., Baimey, H., Goergen, H., Sikirou, R. and Toko, M. 2010. Integrated Pest Management in Vegetable Production: A guide for extension workers in West Africa. International Institute of Tropical Agriculture, Ibadan, Nigeria, pp. 120. [Google Scholar]

Kajembe, G.C., Julius, F., Nduwamungu, J., Mtakwa, P.W. and Nyange, D.A. 2005. Impact of indigenous-based interventions on land conservation: A case study of a soil conservation and agro- forest project Arumeru Districts Tanzania. Journal of land Degradation and Development, 6: 311-325. [Abstract/FREE full text, Google Scholar, CrossRef]

Kalne, A. A., Khan, K. A. and Gadi, C. 2018. Use of ultrasound technology in processing of fruits and vegetables. In: Sehrawat, R., Khan, K.A., Goyal, M.R. and Paul, P.K. (eds.). Technological Interventions in the Processing of Fruits and Vegetables. Apple Academic Press, pp. 185-208. [Abstract/FREE full text, Google Scholar, CrossRef]

Khaliq, A., Mahmood, H.B., Nadeem, M.A., Ahmad, N., Sher, R.U. and Khursheed, M.R. 2020. Benefit cost ratio of buds chips planting and its effects on yield and quality of sugarcane. Advancements in Life Sciences, 7(3): 151-156. [Abstract/FREE full text, Google Scholar]

Kuter, M., Gurskaya, M., Andreenkova, A. and Bagdasaryan, R. 2018. Asset impairment and depreciation before the 15th century. Accounting Historians Journal, 45(1): 29-44. [Abstract/FREE full text, Google Scholar, CrossRef]

Lin, M.Y., Kim, H.J., Yang, T. and Langenhoven, P. 2017. Plant propagation for successful hydroponic production. Acta Horticulturae, 1212: 109-116. [Abstract/FREE full text, PubMed, Google Scholar, CrossRef]

Liu, P. 2013. Trends and Impacts of Foreign Investment in Developing Country Agriculture: Evidence from Case Studies. Food and Agriculture Organization of the United Nations, Rome, pp. 342. [Abstract/FREE full text]

MAFS. 2002. Study on the horticulture development in Tanzania. [Abstract/FREE full text, Google Scholar]

Michler, J.D., Tjernström, E., Verkaart, S. and Mausch, K. 2019. Money matters: The role of yields and profits in agricultural technology adoption. American Journal of Agricultural Economics, 101(3): 710-731. [Abstract/FREE full text, Google Scholar, CrossRef]

Misaki, E., Apiola, M., Gaiani, S. and Tedre, M. 2018. Challenges facing sub-Saharan small‐scale farmers in accessing farming information through mobile phones: A systematic literature review. The Electronic Journal of Information Systems in Developing Countries, 84(4): e12034. [Abstract/FREE full text, Google Scholar, CrossRef]

Munjuga, M.R., Gachuiri, A.N., Ofori, D.A., Mpanda, M.M., Muriuki, J.K., Jamnadass, R.H. and Mowo, J.G. 2013. Nursery Management, Tree Propagation and Marketing: A Training Manual for Smallholder Farmers and Nursery Operators. Nairobi: World Agroforestry Centre, pp. 60. [Abstract/FREE full text, Google Scholar]

Nas, T.F. 2016. Cost-Benefit Analysis: Theory and Application (2nd Ed.). SAGE Publications, London, pp. 252. [Google Scholar]

NBS. 2017. Annual Agriculture Sample Survey Crop and Livestock Report. National Bureau of Statistics, Tanzania, pp. 168. [Abstract/FREE full text]

NBS. 2019. National Food Balance Sheet Reports 2014-2017. National Bureau of Statistics, Tanzania, pp. 63. [Abstract/FREE full text]

Odhiambo, H. 2021. Characteristics of small scale tomato production across four counties of Kenya. Journal of Horticulture, 8(5): 1000p158. [Abstract/FREE full text]

Pandiyaraj, P. 2017. Modern nursery raising systems in vegetables. International Journal of Agriculture Sciences, 9: 4889-4892. [Google Scholar]

PASS. 2013. Investment Potential of Horticulture and floricultural Industry. Private Agricultural Sector Support, Tanzania.

de Putter, H., van Koessveld, M.J. and de Visser, C.L.M. 2007. Overview of the vegetable sector in Tanzania. AfriVeg Project, Tanzania, pp. 32. [Abstract/FREE full text]

Qumbisa, N. D., Ngobese, N. and Kolanisi, U. 2020. Potential of using Amaranthus leaves to fortify instant noodles in the South African context: A review. African Journal of Food, Agriculture, Nutrition and Development, 20(4): 16099-16111. [Abstract/FREE full text, Google Scholar, CrossRef]

Rais, M. and Sheoran, A. 2015. Scope of supply chain management in fruits and vegetables in India. Journal of Food Processing and Technology, 6(3): 1000427. [Abstract/FREE full text, Google Scholar, CrossRef]

Ratha, K., Rajwant, P., Kalia, K., Tewari, J.C. and Roy, M.M. 2014. Plant Nursery Management: Principles and Practices. Central Arid Zone Research Institute, Jodhpur, India. pp. 40. [Abstract/FREE full text, Google Scholar]

Rodriguez-Casado, A. 2016. The health potential of fruits and vegetables phytochemicals: notable examples. Critical Reviews in Food Science and Nutrition, 56(7): 1097-1107. [Abstract/FREE full text, PubMed, Google Scholar, CrossRef]

Sastry, K.S. and Zitter, T.A. 2014. Management of virus and viroid diseases of crops in the tropics. In: Sastry, K.S. and Zitter, T.A. Plant Virus and Viroid Diseases in the Tropics. Springer, Dordrecht. pp. 149-480. [Abstract/FREE full text, Google Scholar, CrossRef]

Sefa, V. A. and Beed, F. 2012. Enhancing vegetable value chains in rice-based and sole crop production systems to improve household income and consumption in Morogoro. Africa RISING East and Southern Africa Research Review and Planning Meeting, Arusha. [Google Scholar]

SEVIA. 2014. Potential positive impact of production techniques on yield. Seeds of Expertise for the Vegetable Industry of Africa Project, pp. 46. [Abstract/FREE full text]

Singh, B. 2021. Unit 2: Nursery Tools and Equipment. Indira Gandhi National Open University, New Delhi.

Sinyolo, S., Ndinda, C., Murendo, C., Sinyolo, S.A. and Neluheni, M. 2020. Access to information technologies and consumption of fruits and vegetables in South Africa: Evidence from nationally representative data. International Journal of Environmental Research and Public Health, 17(13): 4880. [Abstract/FREE full text, PubMed, Google Scholar, CrossRef]

Skoczek-Rubińska, A., Bajerska, J. and Menclewicz, K. 2018. Effects of fruit and vegetables intake in periodontal diseases: A systematic review. Dental and Medical Problems, 55(4): 431-439. [Abstract/FREE full text, PubMed, Google Scholar, CrossRef]

TAHA. 2011. Horticulture Value Chain in Tanzania. Tanzania Horticultural Association. Retrieved from http://repository.businessinsightz.org/. Accessed on April 14, 2022. [Abstract/FREE full text]

TAPP. 2012. Increased Incomes Through Better Farming. Retrieved from https://www.tanzania-agric.org on 27 October, 2020.

TAPP. 2015. Tanzania Agricultural productivity program final report 2009-15. United States Agency for International Development, Tanzania, pp. 52. [Abstract/FREE full text]

Temesgen, M. and Retta, N. 2015. Nutritional potential, health and food security benefits of taro Colocasia esculenta (L.): A review. Food Science and Quality Management, 36: 23-30. [Abstract/FREE full text, Google Scholar]

Temu, A.E. and Temu, A.A. 2006. High value agricultural products for smallholder market in sub Saharan Africa: Trends, opportunities and research priorities. International Center for Tropical Agriculture, Cali, Colombia, pp. 37. [Abstract/FREE full text, Google Scholar]

Tewari, D. 2009. Foundation of Successful Vegetable Production System. University of Chicago Press. Retrieved from http://agropedia.iitk.ac.in/content/nursery-management-vegetable.

UN. 2003. Rise of Supermarkets Across Africa Threatens Small Farmers: Opportunities and Challenges in a Changing Market. United Nations: Meetings Coverage and Press Release. [Abstract/FREE full text]

Waiba, K.M. and Sharma, P. 2020. Study of growth parameters and germination of tomato seedlings in soil-less media under protected environment. Journal of Pharmacognosy Phytochemistry, 9: 308-311. [Abstract/FREE full text, Google Scholar]

Weerakkody, W.A.P. and Mawalagedera, S.M.M.R. 2020. Recent developments in vegetable production technologies in Sri Lanka. In: Agricultural Research for Sustainable Food Systems in Sri Lanka, 189-214. [Abstract/FREE full text, Google Scholar, CrossRef]

Xaba, B.G. and Masuku, M.B. 2013. Factors affecting the productivity and profitability of vegetables production in Swaziland. Journal of Agricultural Studies, 1(2): 37-52. [Abstract/FREE full text, Google Scholar, CrossRef]

Yosef, A., Bekele, K. and Albachew, M. 2013. Innovation platforms for establishment and management of community nurseries in the central highlands of Ethiopia. Journal of African Crop Science, 21: 693-703. [Abstract/FREE full text, Google Scholar]

Profitability, vegetable seedlings, planting technologies, Tanzania.

* Corresponding author

a Department of Applied Economics, School of Economics, University of Dar es Salaam, P.O. Box 35045, Dar es Salaam, Tanzania

b Department of Social Studies, College of Social Sciences and Humanities, The Mwalimu Nyerere Memorial Academy, P. O. Box 9193, Dar es Salaam, Tanzania

c Department of Business Management, College of Economics and Business Studies, Sokoine University of Agriculture, P. O. Box 3140, Morogoro, Tanzania

Emails: selinanombo@gmail.com (S.P. Nombo), paritsaruni@mnma.ac.tz (P.L. Saruni), makj@sua.ac.tz (J.R. Makindara)

This article does not contain any abbreviations to display here.

Received: 25 May 2022

Revised: 16 October 2022

Accepted: 08 November 2022

Published: 31 March 2023

How to Cite

| AMA |

Nombo SP, Saruni PL, Makindara JR. Costs and benefits associated with the adoption of tomato and sweet pepper nursery seed propagation technologies in Arumeru and Mvomero districts in Tanzania. J Hortic Sci Technol. 2023;6(1):7-15. doi:https://doi.org/10.46653/jhst2361007

|

| MLA |

Nombo, Selina P., et al. “Costs and Benefits Associated with the Adoption of Tomato and Sweet Pepper Nursery Seed Propagation Technologies in Arumeru and Mvomero Districts in Tanzania.” Journal of Horticultural Science & Technology, vol. 6, no. 1, 1, 2023, pp. 7–15, https://doi.org/10.46653/jhst2361007.

|

| APA |

Nombo, S. P., Saruni, P. L., & Makindara, J. R. (2023). Costs and benefits associated with the adoption of tomato and sweet pepper nursery seed propagation technologies in Arumeru and Mvomero districts in Tanzania. Journal of Horticultural Science & Technology, 6(1), Article 1. https://doi.org/10.46653/jhst2361007

|

Download Citation (RIGHT CLICK & “SAVE LINK AS”)

This article do not contain any supplementary data.